R & D

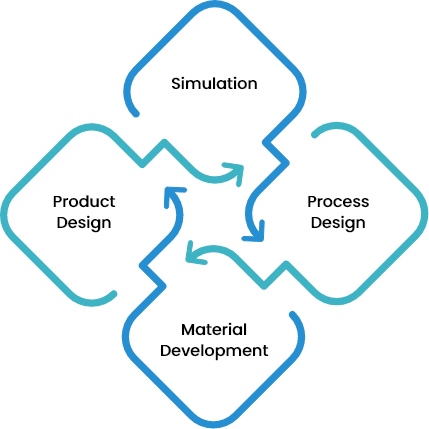

We have been on the forefront to emerge as a solution provider to its customer through its innovative research and development. Having a dedicated R&D facility with state of the art facility for validation and development JK Fenner develops innovative and customised solutions for the customers and emerging markets. Material development, validation, product design , development, simulations and validations forms a systematic approach supported by a strong project management monitoring and adhering to the timelines. Qualified and experienced team form the backbone in driving success for the R&D at JK Fenner.

Design

Materials

Verification

Validation

Program Management

DESIGN

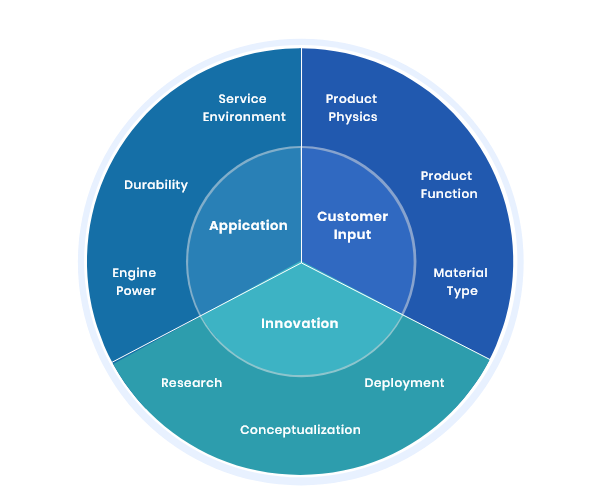

Leveraging Global Knowledge across Market

Scientific approach and expertise helps our customers with solutions and innovative product enabling a first to market launch. The solutions covers new projects as well as dealing with the challenge of enhancing performance and efficiency of existing products. Our goal is to leverage Technology & Innovation / Research and development capabilities to generate distinct value through new, improved products with a competitive edge.

Design capabilities

- Flexible design expertise with unique set of capabilities and experience in all aspects of product design

- Inhouse design team working on CAD models from concept to launch

- Designing performance products and systems meeting the highest standard with quality and value propositions meeting customer expectations across the globe

Design Capability

Flexible design expertise with unique set of capabilities and experience in all aspects of product design

Patents

- Gen 1 Tensioner : Axial Damping : Patent Number: 495228

- Gen 2 Tensioner : Axial + Radial Damping : Patent Number: 543125

- Low torque Railway wheel hub bearing seal. Patent Number: 510031

- Rubber belt having special feature for conveying ceramic tiles. Patent Number: 529410

International Journal Publications

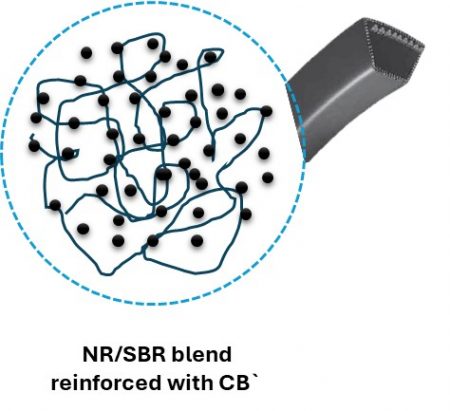

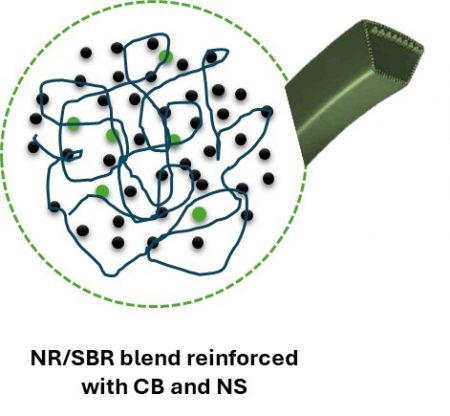

Journal - 1

Article ID : 3101938

Published on : 23 February 2024

Link : https://doi.org/10.1155/2024/3101938

Description : Determination of Dynamic Mechanical Properties on Addition of Carbon Black-Nanosilica Hybrid Fillers in NR-SBR Blends with Special Reference to Power Transmission Belt Applications.

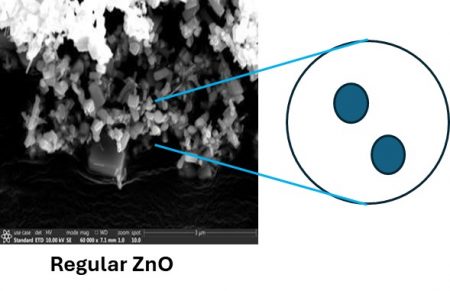

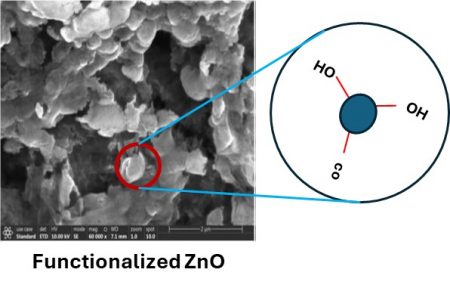

Journal - 2

Article ID : HELIYON-D-24-06617

Published on : 23 June 2024

Link : https://doi.org/10.1016/j.heliyon.2024.e33275

Description : Evaluating the Efficiency of Functionalized Zinc Oxide Based Curing System for Polychloroprene Composites and Analysing its Effect on Curing, Physical, and Morphological Properties for the Application in Specialty Power Transmission Belts

MATERIAL

Proficiency in Material Development

Scientific approach and expertise helps our customers with solutions and innovative product enabling a first to market launch. The solutions covers new projects as well as dealing with the challenge of enhancing performance and efficiency of existing products. Our goal is to leverage Technology & Innovation / Research and development capabilities to generate distinct value through new, improved products with a competitive edge.

- Expertise & experience on wide varieties of Rubber compounding defined by industry, leading innovation to provide comprehensive rubber product & Performance.

- “Best-in-Class“ Analytical & Experimental Laboratory dedicated to material development centre.

- Collaborative development with Global material supplier & customer in achieving advancement in materials.

- Continuous improvement on material technology to fulfil environmental regulation and progress towards Green Chemistry.

- In-house capability to develop compound for extreme application as per customer functional needs.

- Raw material / Formulation level expertise are in-house with the Technologists more than two decades of experience and data.

Relationship

Concept Design

Detail Design

Design Verification

Design Sign-off

Final Design Transfer

Elastomer Capability

| Properties | NR | SBR | BR | IIR | EPDM | CR | CSM | NBR | HNBR | ECO | ACM | AEM |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Oil Resistance | ||||||||||||

| Ozone & Ageing Resistance | ||||||||||||

| Thermal Stability | ||||||||||||

| Mechanical | ||||||||||||

| Low Temperature |

GOOD

MODERATE

POOR

VERIFICATION

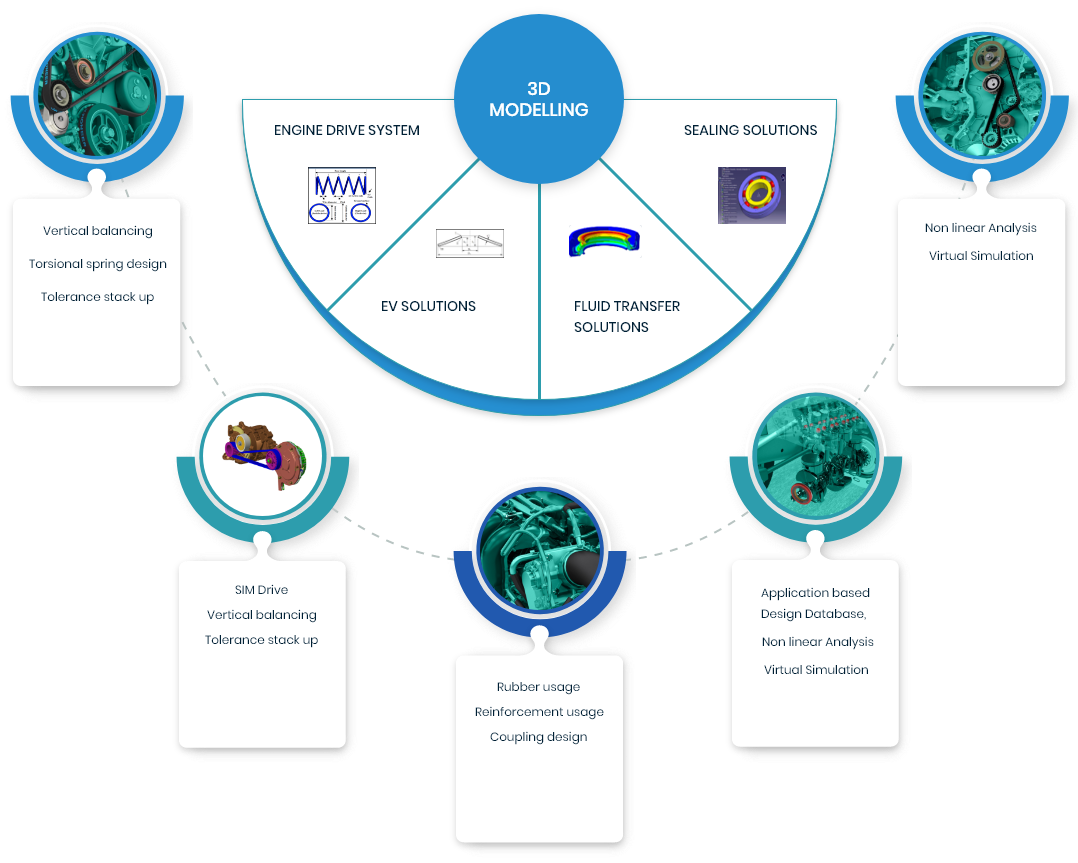

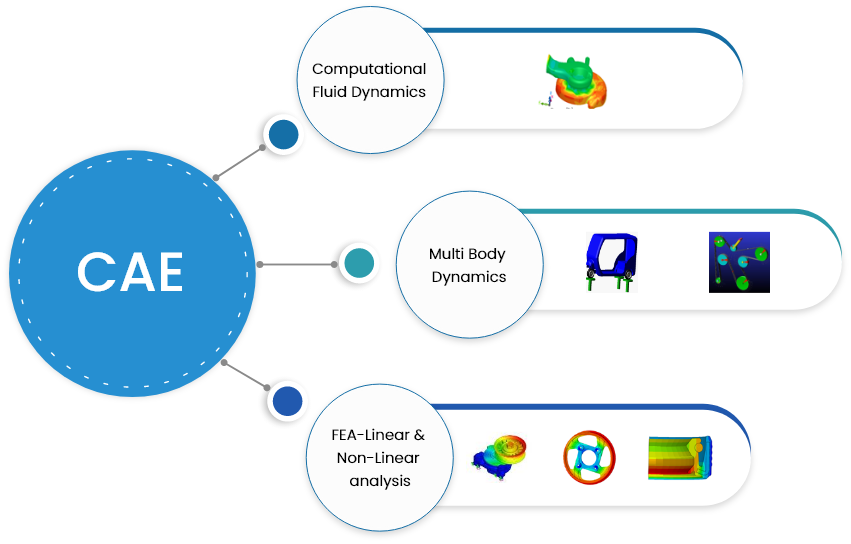

CAE Capability

Product design and simulation is constantly upgraded and used by JK Fenner to virtually optimize product and system design. This helps in scientifically proving the concepts and reducing the time for proto validation and iterations

- A dedicated team working on analysis with the latest software’s for linear and non linear materials

- Use of complex techniques leveraging on its CAD, FEA, MBD , CFD and fatigue analysis to ensure development of products and system with minimum possible time meeting the demanding quality , durability and safety requirements

VALIDATION

Leverages its strength on product knowledge and application in simulating and building up test protocols. All the products developed are validated in simulated actual service conditions to achieve the inbuild design reliability

- 83 test rigs custom build for all applications to simulate actual service conditions.

- Each bench are programmable and adaptable to validate custom test cycles, environmental, frictional and thermal simulations

- Expertise to conduct engine test bed validation, fleet validation & System performance test for belts and tensioners

Oil seal Durability & application Simulation

FEAD Tensioner validation Test Rig

Pulley & Bearing durability

Water Pump durability

Fleet Validation

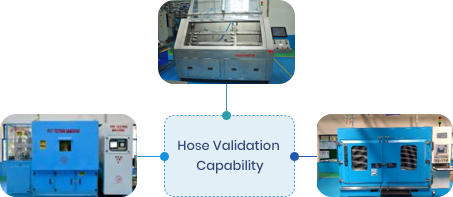

Hose Validation Capability

Belt Validation Capability

Material Testing

Program Management

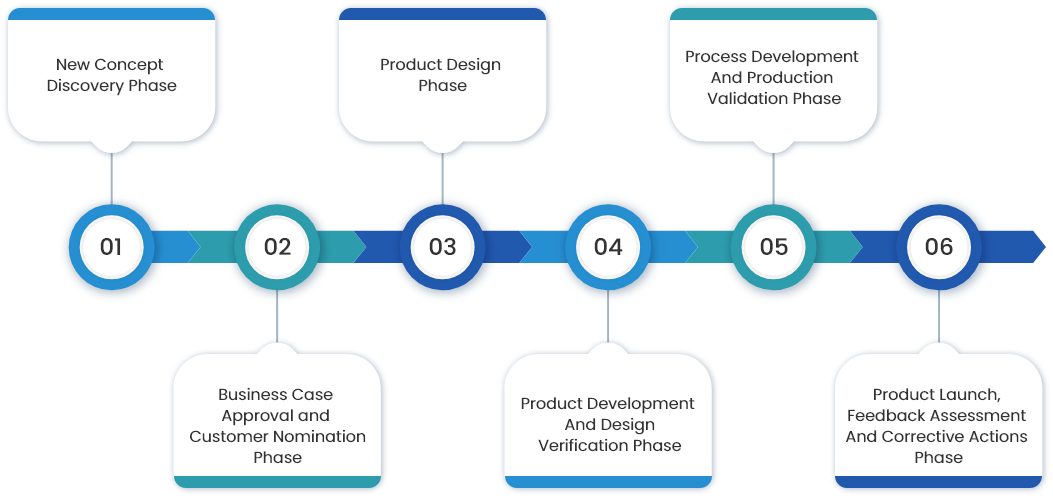

Program management is the core to drive the projects across all product families at JK Fenner. Customised PLM applications has been developed and is practiced to achieve and meet the program time lines with systemized stage reviews.

- APQP process customized across all product families through PLM application

- Role based access controls and reviews to track multiple project status and change management

- Adoption of Funnel – Bugle (FuGle) innovation process model in defining a product centric 6-phase project lifecycle system common to multiple business verticals and product families