Sustainable Manufacturing

Our commitment towards a Cleaner, Greener, and Sustainable Future

The Short story - of Our Long history of Sustainability

- We recognize that our Planet is faced with severe Environmental and Ecological challenges – greatest of them being Resource depletion, Climate Change and Ecological disturbance. These are fast transforming the global economic, regulatory, and business environment.

- We are thoroughly aware of the persisting challenges of societal inequalities, exploitation, poverty and the health crisis that need to be addressed swiftly.

- As a responsible Organisation, we are committed to contribute in transforming to a Greener and more equitable future through Sustainable development practices.

- We continually strive to have a progressive influence on our people, stakeholders and the communities we work in by strictly adhering to fair practices and ethics across our operations, encompassing all our transactions.

- Sustainability is embedded as a core philosophy across the Organisation and we see Sustainable development as an essential business practice.

- We have made significant strides in Sustainability with our initiatives beginning since year 1994, when we setup our first Green energy plants.

ESG – Material Areas for JKF

- A comprehensive Materiality assessment has revealed the key Environmental, Social and Governance (ESG) issues relevant to JKF, that are as follows:

Environment

- Carbon Emissions

- Water Security

- Energy Management

- Waste Recycling

- Product Life cycle

- Product Stewardship

- Biodiversity

Social

- OHS

- Diversity & Inclusion

- Human Rights

- Ethical Labour Practices

- Product Safety

- Talent Engagement and Retention

- Customer Health and Safety

Governance

- Cyber Security & Data Privacy

- Ethical Business

- Compliance Commitment

- Innovation and Digitalization

- Responsible Value Chain

- Economic Value Creation

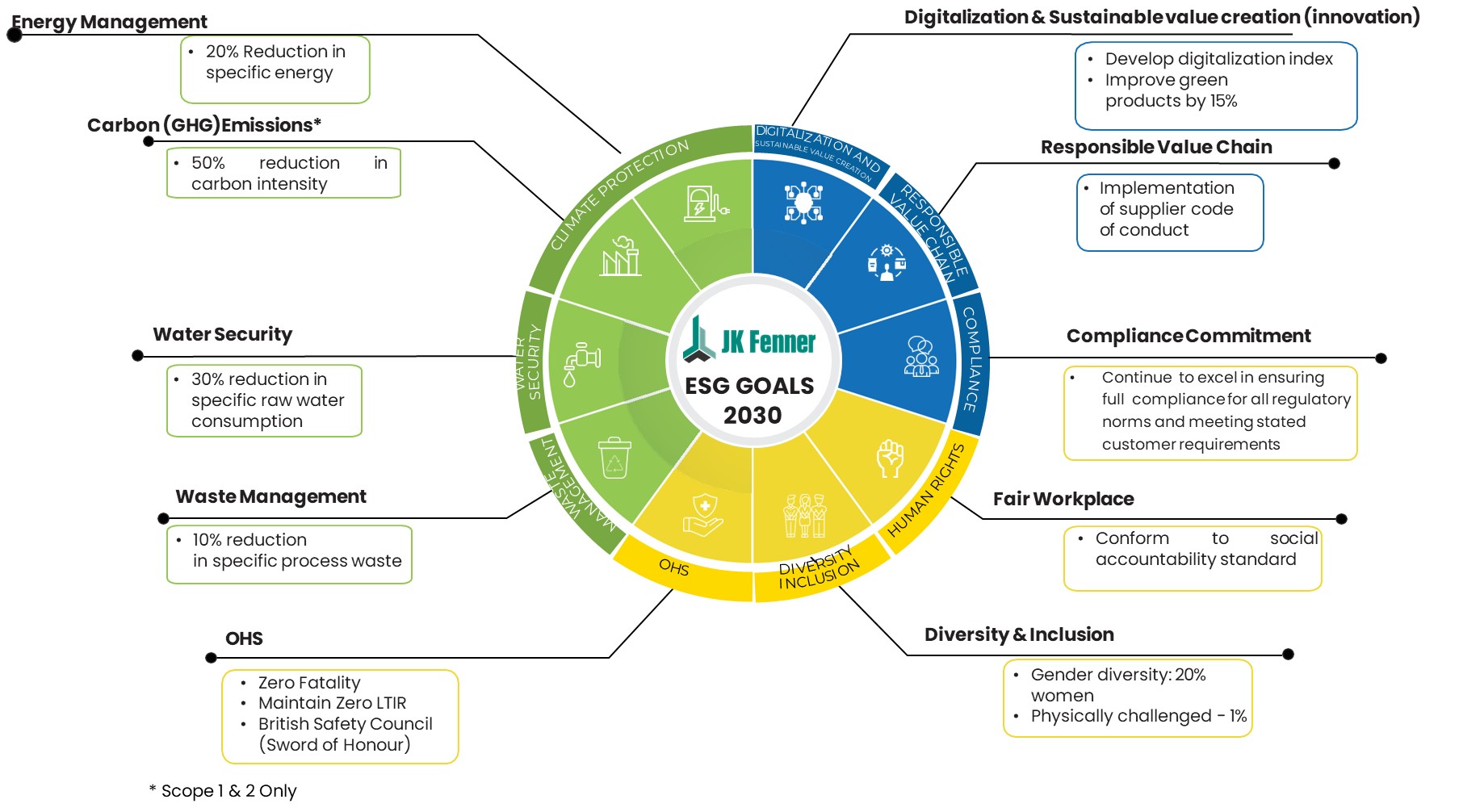

Towards a Sustainable Future - Our ESG Goals (2030)

- In our journey towards sustainable future, our ESG Vision is clearly articulated to the entire team by the top leadership. We are committed to create a Sustainable future for all.

- Our Sustainability strategy constitutes the current Environmental priorities of Energy & Water conservation, Green House Gas (GHG) abatement, Waste minimisation, Greener materials & products and Pollutant reduction. Diversity, Human rights, Well-being and Innovation are our key focus areas under the Social and Governance facet.

- We have set ambitious ESG goals based on our business trajectory that are aligned to global & national SDGs and customer ESG goals, while being practical with a clear roadmap.

- We at J.K.Fenner focus on Environment, Social and Governance and they form the three pillars of our strategy. LEAN tool is used for resource consumption reduction to take care of environment, 3R tool is used for resource management and Abatement of CO2 for GHG net emission reduction to achieve our sustainability goal.

ESG Goals 2030 *

Our Sustainability Initiatives

We have Carried Out Several Sustainability Initiatives In Our Green Journey by installing wind mills & solar plants. We understand that to move forward on Sustainability, we need to be backing down our Resource use. Its not a matter of short term measures, rather a marathon of consistent efforts.

Renewable Energy (RE)

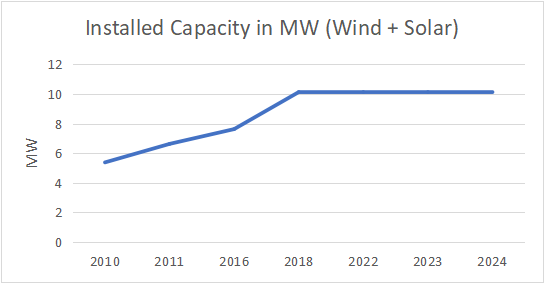

In our pursuit to GHG abatement, we as an organisation have opted for greener power by installing wind mills for our plant operations (1994 onwards) and diversified into solar power from 2016.

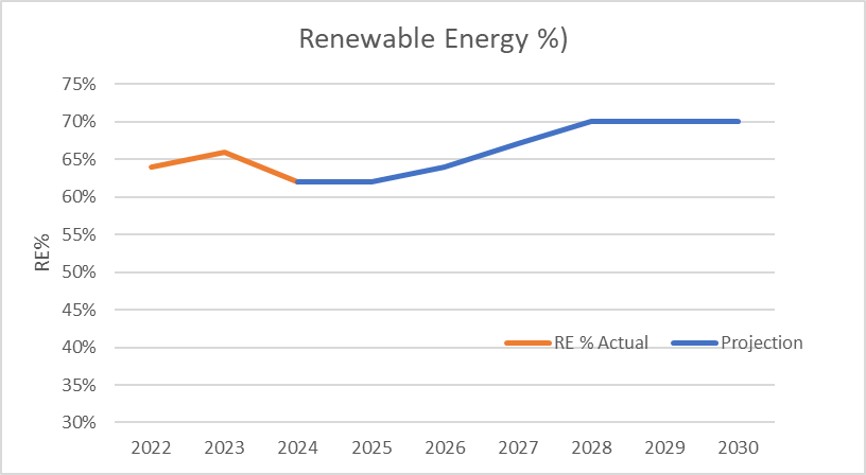

- 2030 Goal:70% Electricity from Renewable sources (>90% in three plants)

- We are a Pioneer in Renewable Energy adaptation and installed wind mills as early as 1994

- 30 years of Renewable energy contribution to the country

- 325 Million Units of Green power generated

- 16.5 Million Units per year presently

- 10.125 MW installed capacity

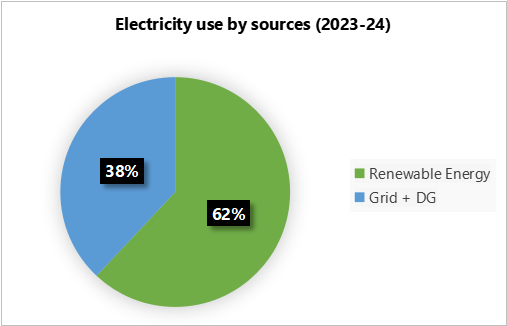

- Green Power constitutes 62% of Electricity used by the Company

- Maximisation of RE% is underway through both on-site and off-site RE adoption.

62% Electricity from Renewable sources (2023-24)

62% Electricity from Renewable sources (2023-24)

RE % Actual and Plan to 2030

Water

India as a country continues to be deprived of safe drinking water. The country ranks among the top most water starved in the global ranking and we as a responsible corporate citizen have taken water conservation as a major initiative in all our plant operations. The 3R approach is taken along with innovation in manufacturing process as a continuous journey to become net water neutral in the years to come.

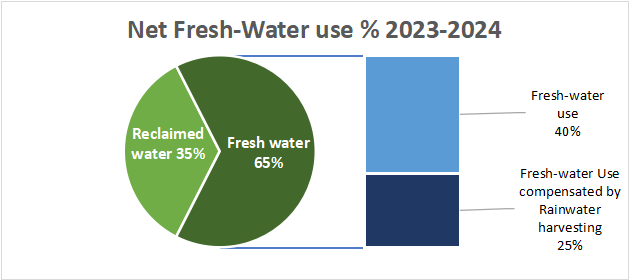

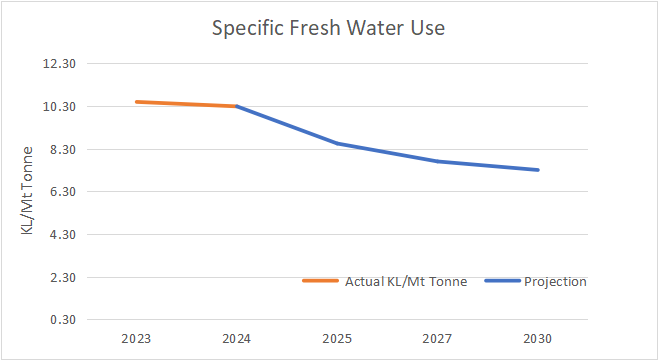

- Goal 2030: 30% Reduction in specific fresh water use (base year 2023).

- Vision 2040:Net Zero Water in Manufacturing plants.

- 100% Wastewater treatment and Recycling is implemented in all our facilities through Effluent and Sewage treatment plants. Recycled water is fully utilised in-house for process requirements, domestic flushing use and gardening.

- Reduce and Recycle has been our Mantra on Water.

- Rainwater harvesting strategies using storage tanks, ponds and percolation systems are implemented at all our plants, enabling 50 Mn litres of water being recharged to the ground annually.

- Harvested rainwater quantity equals 36% of our fresh-water usage.

- Considering the water recharged by Rainwater harvesting, Net Fresh-water sourced constitutes less than 40% of the total water usage, 60% being reclaimed water.

- Specific fresh water use reduced every year by continuous process optimisation and controls

Specific Fresh Water Use Actual and Plan to 2030:

Energy Efficiency

In our pursuit to become a net carbon neutral organisation, we always believe that LEAN principle applied in all our resource consumption will enable us to reach the goal. Hence the energy efficiency initiative is driven across plants on a continuous basis for more than a decade and lot of innovations have been implemented year on year. Periodical third part energy audits are conducted across plants and best practices are shared across plants. The industry bench mark is done on a continual basis and the road map are redefined to be the best in the industry.

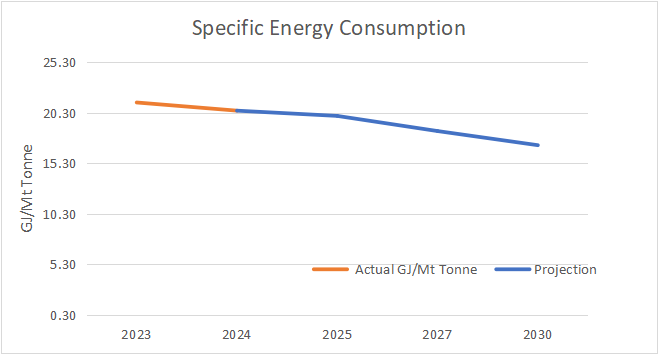

Goal 2030: 20% Reduction in specific energy consumption (base year 2023)

- Energy Conservation is not only a cost reduction priority, but a Habit imbibed in to our work force since long

- Energy efficiency projects such as Technology upgrades, Process optimization and loss reduction are a regular on-going activity at all our units

- Specific Energy Consumption (SEC) reduction of 3%-5% per year, owing to Energy efficiency projects and better capacity utilisation.

- Annual savings of 0.5 Million units of electricity and 3600 GJ of fuel

Specific Energy Consumption Actual and Plan to 2030:

GHG Management

Global warming is a big challenge the planet Earth is facing and CO2 emission plays a major role. Understanding the problem, we as a responsible corporate citizen have taken several initiatives in our energy consumption by adopting greener technologies like renewable energy and Bio Mass. The 3R principle is applied wherever possible.

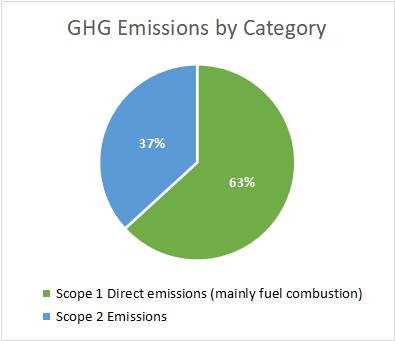

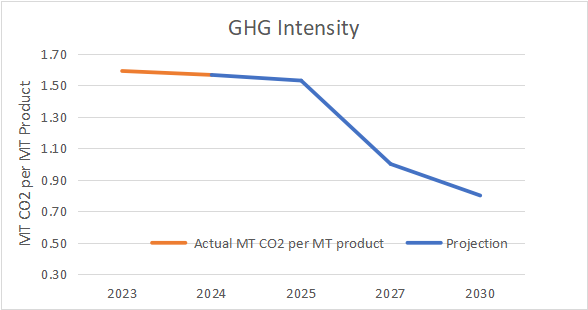

Goal 2030: 50% Reduction in GHG intensity (In Manufacturing plants, base year 2023, Scope 1&2)

- We are inherently a Planet friendly Organization.

- Emission reduction projects have been identified through a GHG Inventory study

- Key De-carbonization leversare: Increasing Renewable electricity use, Gas & Bio-fuel adoption, Electrification of heating applications and Technology upgradation.

- We are actively working on an Energy Transition strategy to migrate towards low carbon sources.

- Global Recognition: Our Wind power project has been Certified by the United Nations Climate body as a Clean Development Mechanism (CDM) project

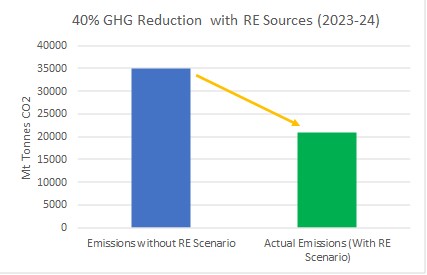

- Carbon emissions in manufacturing during 2023-24 was 21006 Mt Tonnes CO2 (Scope 1&2), main sources being fuel oil and grid electricity. This would have been 60% higher without renewables and energy efficiency.

- 260,000 Mt Tonnes of CO2 reduced by our renewable plants over 30 years – equivalent to 115,500 mature trees

- Our Raw materials constitute significant embodied carbon. Through continuous R&D, we have successfully reduced the embodied carbon by 10% to 20% in several product categories. We further plan to engage the supply chain to explore more sustainable raw materials.

GHG Emissions by category

40% GHG Reduction with RE Sources (2023-24)

GHG Intensity Actual and Plan to 2030:

Product & Sustainability

To contribute to the sustainability, we continuously enhance our product performance and the products are designed with greener materials to reduce the load on natural resources. LEAN principle is applied throughout our operations to produce more from less on a continuous basis.

Product Sustainability

We are Global leaders in Energy Efficient Power Transmission products. All our products deliver top of the class energy efficiency resulting in Energy savings for our customers throughout its lifecycle. Our R&D Team continuously works on improvising its existing products to be more sustainable (recycled & low carbon materials, weight reduction, reduced chemical usage). Our R&D team has successfully reduced Virgin raw materials use in the production by substituting with natural fillers and Reclaimed rubber.

We are also developing certain innovative automotive components for the EV industry, including EV motors, EV drives etc.

Innovation

We have embraced Digitalisation across the Organisation in all our Business processes – Industry 4.0, Data Analytics, Virtual Reality for Trainings, Dealer Management System etc., all of which have contributed to significant reduction in resource use and business travel.

Our workforce has imbibed the culture of Innovation with numerous innovative ideas implemented in the manufacturing process and new product development.

People & Community

We as an organisation believe that people are very important to take the sustainability Vision forward. Creating a great place to work is one of our endeavour to create a motivated team. The sustainability initiatives are taken out side the boundary of the organisation to the society and we try to give back what we have taken.

2030 Goals: Zero Fatality, 20% women in workforce, Compliance with Social Accountability Standard

People

- Our People stand behind our Sustainability achievements

- Our plants are ISO 45001 certified and imbibe an open and positive work culture.

- Adequate policies and committees are implemented to ensure an Equitable, Safe and non-discriminatory workspace.

- Regular training programs are conducted on various Resource conservation and Green practices.

- Received “Great place to work” certification.

Community

We have a comprehensive CSR program that identifies and addresses key issues in our communities and made positive impact on over 500000 lives. The program details and impacts can be found in our CSR webpage.

Beyond the Fence sustainability initiatives include Tree plantation drives, Restoration of Water bodies.

Management System & Compliances

To ensure that the organisation is aligned to the sustainability vision , robust management systems are in place. Periodic internal and external audit facilitates the effectiveness of implementation and the adherence. A well structured review forum is in place and all the compliances are reviewed by Leadership team in a defined frequency.

Effective Communication and Validation:

We are ISO 14001 and ISO 45001 Certified.

We have published our First Sustainability Report (2023-24), which will be an annual feature going forward.To further strengthen our credibility and transparency, we are actively working towards:

- Carbon Footprint Validation

- Social Accountability certification

- Energy Management System certification

- SBTi commitment

- EcoVadis reporting

- Single Use Plastic (SUP) free