Gear boxes / Geared Motors

Tough Nut –In-line Helical Geared Motor – FH Series

- DESIGN CONCEPTS: the combination of standardization and modularization allows interchangeability with international leading brands, while keeping structure rigidity and compactness.

- ENERGY EFFICIENCY: leveraging the advantage of high accuracy of helical gears, the reducers perform at 90% efficiency with higher stability and lower noise level.

- RATIOS COVERAGE: 1~3 stages of reduction provides a wide range of ratio accommodation from 1/1.3~1/27788.

- LOADING CAPACITY: available with power ranges from 1/4hp up to 150hp depending on different requirements and applications.

- TENSILE STRENGTH: pinion and gears are made with 20CrMo alloy steel plus carburizing heat treatment to enhance performance; the input pinion is equipped with double bearing support to provide stability at high speed.

- COMPLETE SERIES: vertical and horizontal mounting along various input mechanism ensure the products meet a wide range of applications.

- INSTALLATION FLEXIBILITY: all models are designed for a choice of mounting position (M1~M6) specified by customers.

- APPEARANCE AESTHETICS: the products are designed with modern exterior while maintaining high rigidity..

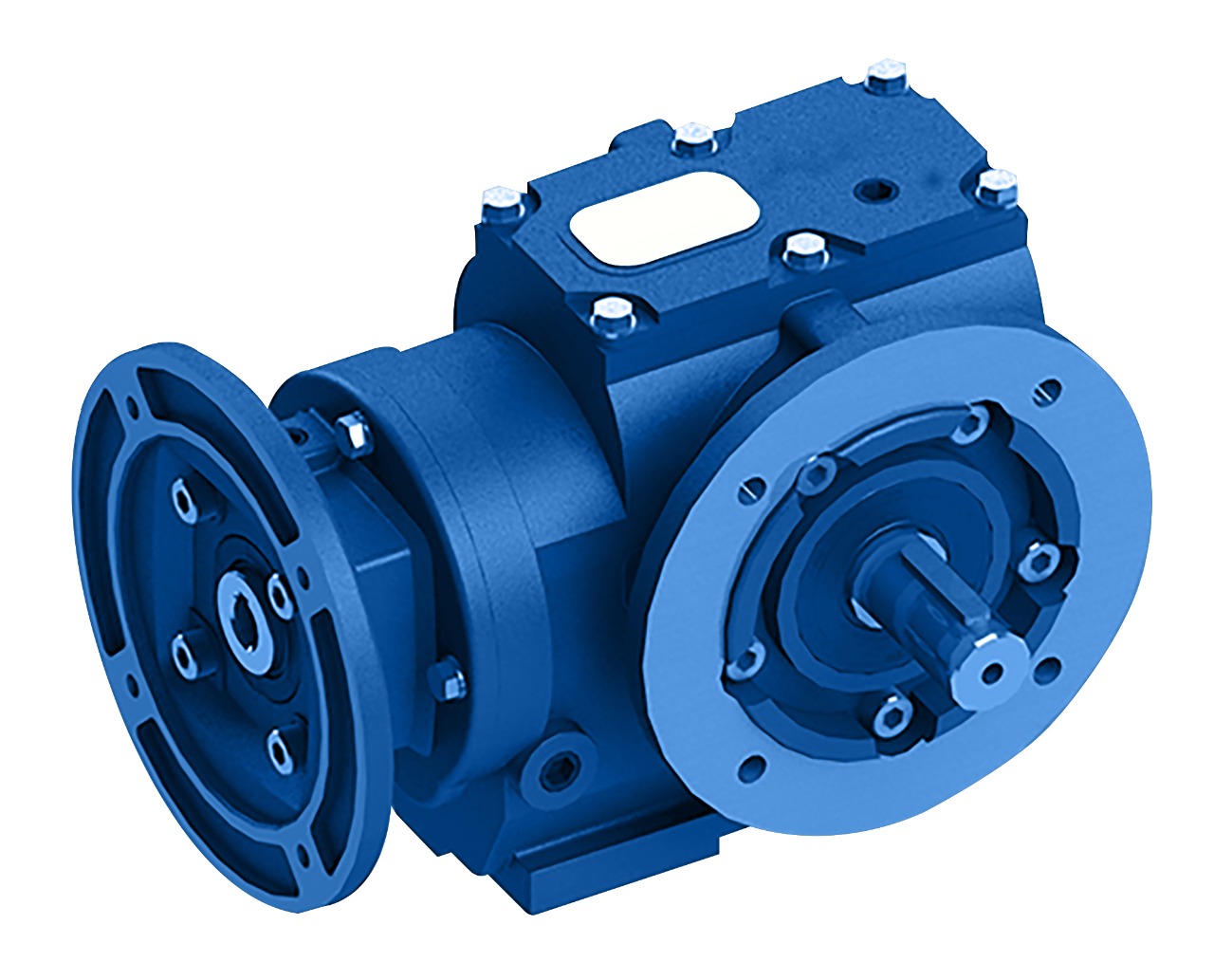

Tough Nut – Bevel Helical Gear Reducer – FK series

- DESIGN CONCEPTS: the combination of standardization and modularization allows interchangeability with international leading brands, while keeping structure rigidity and compactness.

- ENERGY EFFICIENCY: leveraging the advantage of high accuracy of helical gears, the reducers perform at 90% efficiency with higher stability and lower noise level.

- RATIOS COVERAGE: 3 stages of reduction provide a wide range of ratio accommodation from 1/8~1/215 more than worm gear reducers.

- LOADING CAPACITY: available with power ranges from 1/4hp up to 60hp depending on different requirements and applications.

- TENSILE STRENGTH: bevel gears and helical gears are made with 20CrMo alloy steel plus carburizing heat treatment to enhance performance.

- SPACE EFFICIENCY: 90° transmission and compact configuration for minimizing mounting space.

- INSTALLATION FLEXIBILITY: all models are designed for a choice of mounting position (M1~M6) specified by customers.

- APPEARANCE AESTHETICS: the products are designed with modern exterior while maintaining high rigidity.

Tough Nut –Parallel Shaft Helical Gear Reducer – FF series

- DESIGN CONCEPTS: the combination of standardization and modularization allows interchangeability with international leading brands, while keeping structure rigidity and compactness.

- ENERGY EFFICIENCY: leveraging the advantage of high accuracy of helical gears, the reducers perform at 90% efficiency with higher stability and lower noise level.

- RATIOS COVERAGE: 2~3 stages of reduction provides a wide range of ratio accommodation from 1/4~1/254.

- LOADING CAPACITY: available with power ranges from 1/4hp up to 60hp depending on different requirements and applications.

- TENSILE STRENGTH: pinion and gears are made with 20CrMo alloy steel plus carburizing heat treatment to enhance performance.

- SPACE EFFICIENCY: compact configuration for minimizing mounting space.

- INSTALLATION FLEXIBILITY: all models are designed for a choice of mounting position (M1~M6) specified by customers.

- APPEARANCE AESTHETICS: the products are designed with modern exterior while maintaining high rigidity.

Tough Nut – Helical Worm Gear Reducer – FS series

- Design Concepts: The combination of standardization and modularization allows interchangeability with international leading brands, while keeping structure rigidity and compactness.

- Energy Efficiency: Leveraging the advantages of high efficiency of helical gears and smooth transmission of worm gears, the reducer performs with outstanding stability and efficiency as high as 85%.

- Ratios Coverage: The ratio ranges between 1/8 ~ 1/210, providing wide range of ratio accommodation, with 2 stages of reduction.

- Loading Capacity: Available with power ranges from 1/4HP up to 30HP, depending on different requirements and applications.

- Tensile Strength: Pinion, gears and worm shafts are made with 20CrMo alloy steel with carburization; the aluminum bronze worm wheels offers superior strength and endurance.

- Self-Lock: In certain condition, the load on the worm gear can’t drive the worm.

- Installation Flexibility: All models are designed for a choice of mounting position (M1~M6) specified by customers.

- Appearance Aesthetics: The reducers are designed with modern exterior while maintaining high rigidity.

Worm Reduction Gear Box – FA/FU/FV Series

- The casing is made of closely-grained FG-260 Grade C.I

- The Gearbox is provided with well-designed fins and fans for adequate dissipation of heat

- The design is based on BS 721:1963 Class A standards

- The Gearbox Design is modular and makes it interchangeable with other standard gearboxes

- The Worm shaft is built with high-quality case-hardened steel that is precision-manufactured and ground-finished for better performance

- Both Worm & Worm Wheel Shafts are mounted on High-quality Taper Roller / Angular contact Bearings to handle axial thrust and overhung loads

- All Worm Gearboxes are available in Ratios of 5:1 to 70:1

- Type- Horizontal/Vertical/Adaptable Gearbox

Shaft Mounted Speed Reducer

- Mounted directly on the shaft and does not require a foundation.

- Eliminates the need for coupling and potential alignment variations.

- Options: Foot Mount/Flange Mount/Motor Mounting/Vertical Shaft Mounting/Back Stop.

- Comes in 8 sizes B, C, D, E, F, G, H & J.

- Maximum Torque (O/P) – 6995 Nm @10rpm.

- 3 Ratios 5:1, 13:1, and 20:1

- A wide range of output speeds can be obtained by using appropriate input V-Belt drives.

- Choice of alternative hub bores.

- Delivers 98% efficiency per stage of reduction.

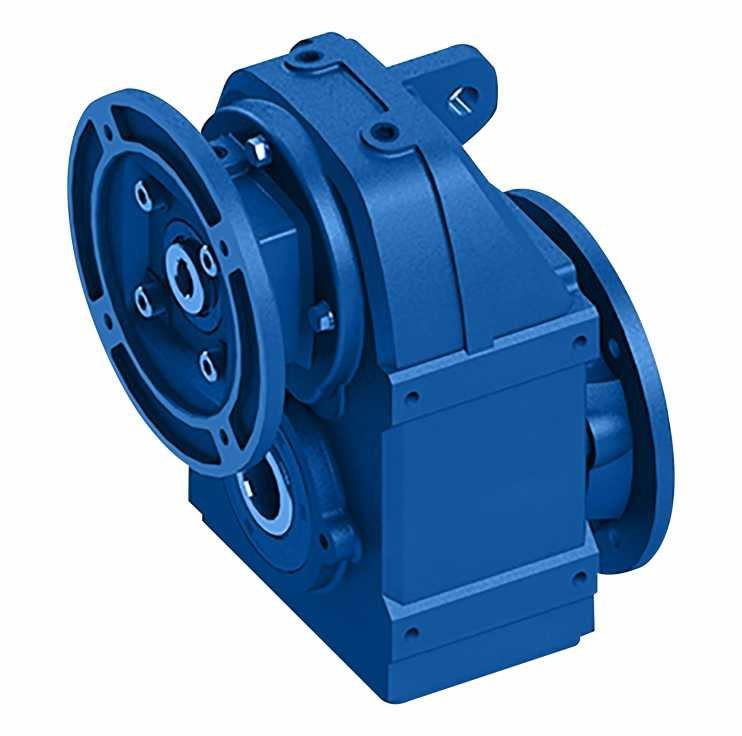

Parallel Helical Geared Motor – PHGM

- Available in 8 Model – B, C, D, E, F, G, H & J.

- 12 ratios are available ranging from 5:1 to 63:1

- Nominal Input Motor RPM is 1440.

- Backstop available in Adaptor Flange.

- Hollow output Hub with Standard & alternate bore sizes.

- Flange design supports vertical Mounting applications.

- Torque arm and Anti Vibration Bracket assembly are available as accessories.